What Sets Us Apart

- One of the most high-tech CNC machining operations in the Oklahoma area

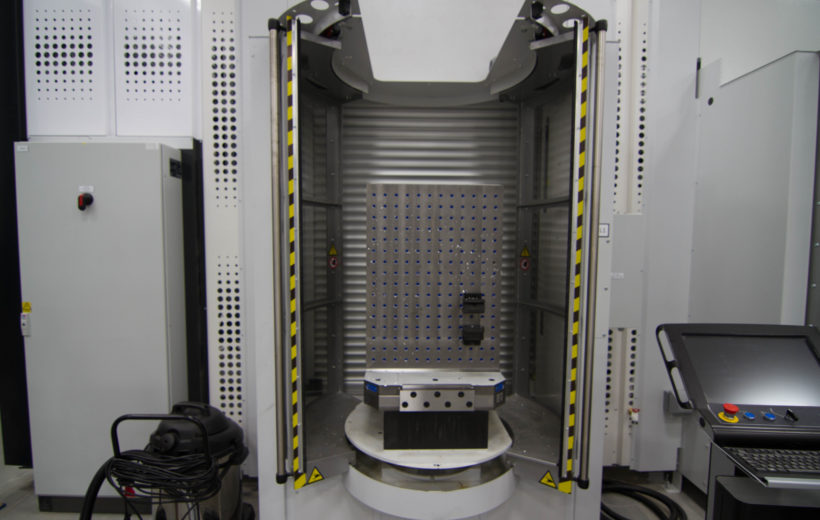

- ValtecCNC uses the Okuma MA-600HII horizontal machining center to achieve highly accurate, consistent machining of mass or low quantity orders

- Our HMC produces everything from heavy-duty machining to complex precision work and uses a variety of machining processes to offer many manufacturing solutions

- Our FMS system and its scheduling software provides lights-out operations 24/7, with up to 300 tombstones and ten machine tools

- Large capacity cutting tools set us above the rest

- 1st machine dedicated to high speed aluminum machining

- Short lead times for fast delivery without jeopardizing quality of the product

- Programs and manufacturing processes are maintained to eliminate set-ups on all repetitive jobs for customers to save time when the job is needed again – that means no set-up time for additional runs or exposure to quality defects by taking advantage of no first article re-setup

- Our CMM inspection process ensures product quality verification

- We use Unigraphics software for state-of-the-art graphics, CAD modeling, and programming

- Equipment is factory maintained

- State-of-the-art laser technology is used to detect broken or worn cutters

- Newly constructed clean facility built in 2015

ValtecCNC is committed to reducing cost, waste, and environmental impact with our Metal Chip Recycler, Chip Reclamation, Coolant Reclamation, and Geothermal Climate Control System.